Our Project Gallery

Services We Provide

Injection Moulding Machine Solutions

At Yumoto Kikai, we deliver Japan made plastic injection moulding technologies designed to meet the evolving needs of manufacturers. With decades of expertise and a commitment to quality, our services help you boost productivity, precision, and profitability.

Customized Machine Selection & Consultation

Not sure which machine fits your production needs?

Our experts guide you to the perfect injection moulding solution based on your material, product size, cycle-time, and budget requirements — ensuring you get maximum efficiency from your equipment investment.

What we offer:

- Expert machine recommendations

- Material-specific advice (thermoplastics, PET, engineering plastics

Production requirement analysis

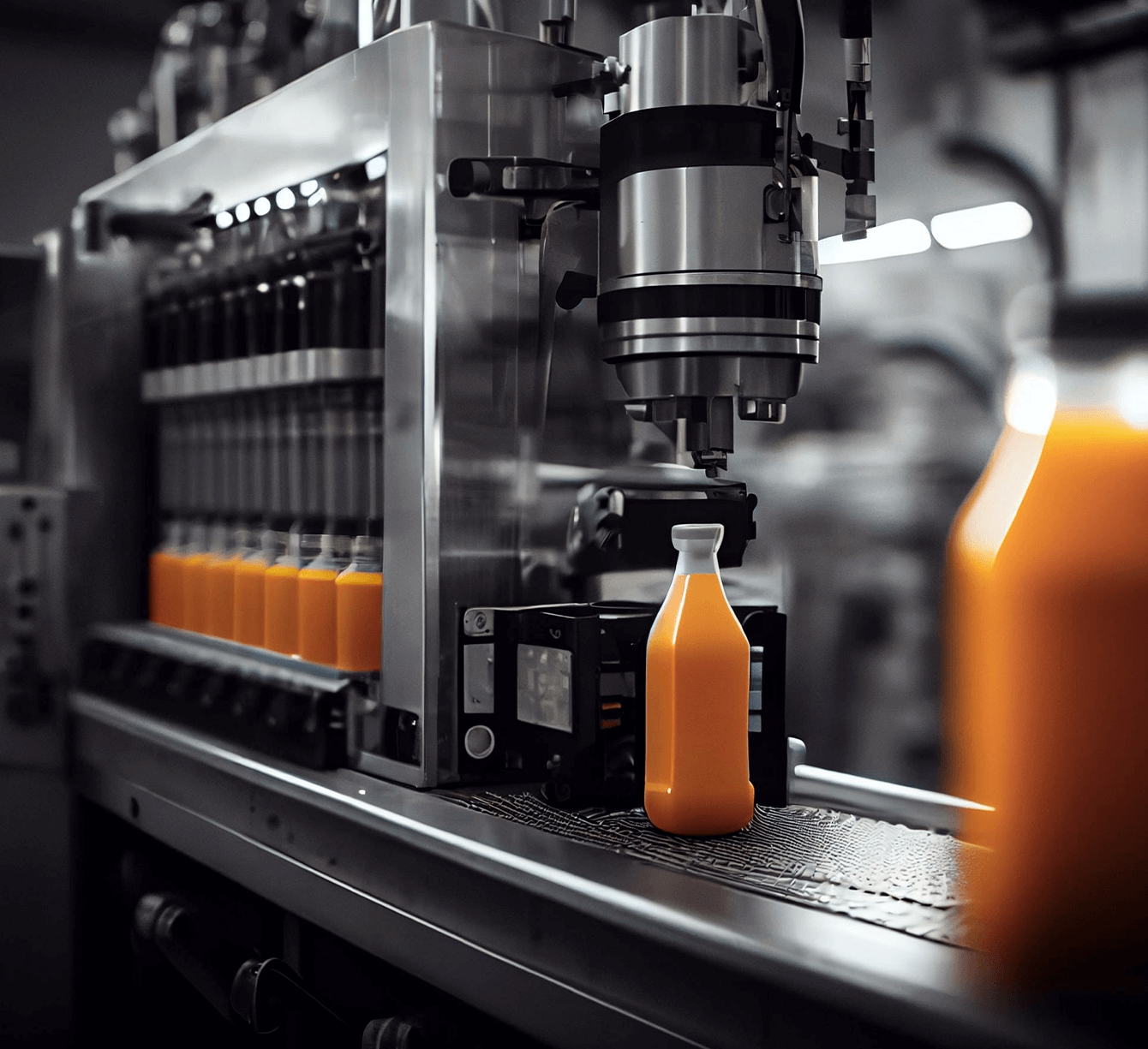

High-Performance Injection Moulding Machines

We supply a range of durable, energy-efficient injection moulding machines — built with precision and designed for industrial reliability. We’ve got the right solution for your production goals.

Key machine types we support:

- Hybrid Machines — optimized balance of power and efficiency.

Electrical Injection Moulding Machines — for energy savings & precision.

Customization & Engineering Support

Every product and production line is unique — and so should your machinery.

Our engineering team can customize machine configurations to suit specialized applications or product designs.

Custom services include:

- Tailored machine modifications

- Control system programming

Performance tuning for specific plastics or parts

Installation & Commissioning

Our trained technicians ensure your machine is seamlessly installed and fully calibrated for optimum performance. From electrical setup to software configuration, we support your team every step of the way.

After-Sales Support & Maintenance Services

We offer responsive after-sales service to minimize downtime and maximize machine life.

Whether you need spare parts, technical troubleshooting, or scheduled maintenance, our team is here to help.

Support features:

- Spare parts supply

- Technical troubleshooting

Preventive maintenance & servicing

After-Sales Support & Maintenance Services

We offer responsive after-sales service to minimize downtime and maximize machine life.

Whether you need spare parts, technical troubleshooting, or scheduled maintenance, our team is here to help.

Support features:

- Spare parts supply

- Technical troubleshooting

Preventive maintenance & servicing

Work Flow

Worldwide Branches

ATSUGI CITY KANAGAWA KEN JAPAN

- 2622-1 Kamiogino Atsugi Shi Kanagawa Ken Japan

- info@yumotokikai.com

- +81-46-258-9046

Ningbo Yumoto Precision Machinery Co.,Ltd

- 201 Xinlian Road, Gaoqiao Town, Haishu District, Ningbo City, Zhejiang Province

- sales@yumotomachine.com

- +86-574-8897-7367

SKN Engineering (Pvt) Ltd.

- F/5c,Block-F S.I.T.E,Super Highway Phase-11,Scheme-33,Karachi,Pakistan

- irfan.ali748@yahoo.com

- +92-300-9226843

Russia Moscow

Thailand Bangkok

People's Comments Regarding Our Services

Hand Picked Machinary Tools

-

Select options This product has multiple variants. The options may be chosen on the product page$125.00 – $180.00

Select options This product has multiple variants. The options may be chosen on the product page$125.00 – $180.00 -

Select options This product has multiple variants. The options may be chosen on the product page$55.00 – $80.00

Select options This product has multiple variants. The options may be chosen on the product page$55.00 – $80.00 -

Select options This product has multiple variants. The options may be chosen on the product page$48.00 – $70.00

Select options This product has multiple variants. The options may be chosen on the product page$48.00 – $70.00 -

Select options This product has multiple variants. The options may be chosen on the product page$180.00 – $200.00

Select options This product has multiple variants. The options may be chosen on the product page$180.00 – $200.00